-

Email: [email protected]

-

Call Now: +91-129-4113000

Using the latest NX 9.0/Solid Edge Siemens software, Forgewell can design the forging dies, and deliver product samples in one week if necessary and always within three to four weeks. All die blocks are machined in the hardened state in DIN 1.2714 material.

We have a fully equipped chemical testing lab for carrying out accurate quantitative analysis of common elements like C, Mn, Si, S, P, Cr, Ni, Mo etc using an Optical Emission Spectrometer. We also carry out Hardness Test, Step Turning & Upset Testing. For Case Hardening Grades we also carry out Jominy Hardenability test. Mechanical Properties like Tensile Strength, Yield Strength, Reduction of Area, % Elongation, Charpy Test is also provided for individual heat from qualified independent laboratories as and when required.

Installed Capacity of 12,000 Tons per annum

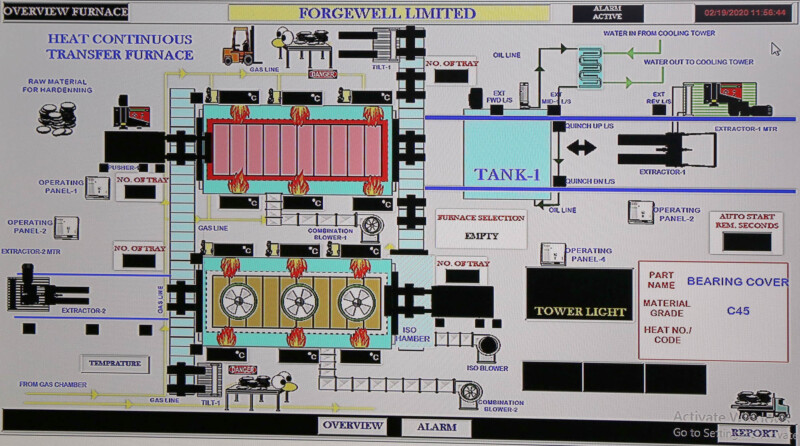

We have inhouse continuous furnace for heat treatment with a capacity of 1Ton/hour. The furnace has advanced SCADA control system for plant Supervisory Control and Data Acquisition.

We can provide following type of Heat Treatment in our components:

Machining:

Inspection: